FOOD INDUSTRY

Contamination of food is a growing worldwide concern : tests show that 90% of food contamination takes place during production and processing. Food industry follows severe cleaning and sanitizing procedures to kill all kinds of bacteria, pathogens and germs. Traditional cleaning provides a 4-stage process : the initial cleaning with water and detergents, the subsequent chemical disinfection (normally with chlorine or acid-based substances) , then rinsing and drying. Using industrial steam machines, this process becomes cost-saving, faster and easier: dry steam cuts line downtimes, saves chemical costs, grants total sanitizing and killing of microorganisms, because of the heat shock.

The cleaned surfaces are left dry; unlike other cleaning methods, steam can reach even the smallest surface cracks and crevasses and can be used on electrical parts, too.

Areas of application: some examples which include:

- cleaning and degreasing of conveyor belts, cylinders and gasket

- cleaning and maintenance of air ducts

- degreasing of control boards and electrical panels

- cleaning and sanitizing of scales and blending tanks

- sanitizing of refrigerated counters

- removal of food residues

- cleaning of workbenches, walls and ceilings

- sanitizing of filters and grills

CATERING

There has been a growing awareness of the need for effective cleaning in all areas where food is involved and standards of hygiene are high. In food preparation, there are many factors involved in keeping the environment hygienic and clean , including the cleaning procedures that should be documented with processes defined so that operators know when where and how cleaning has to be carried out.

Further, the cleaning machines used should provide the most efficient and cost-effective solution to the cleaning issue, to ensure that hygiene standards are met. Our dry steam technology is the ideal tool to grant the effective level of hygiene required for catering equipment and food preparation areas and ensure there is no contamination to the end product.

Areas of application: some examples which include:

- greasy floors cleaning and disinfection

- sanitizing of stainless steel benches and chopping boards

- cleaning of all machineries: stove tops, ovens, mixers, fridges, dish-washers, ice-cream dispensers, etc.

- removal of grease and deposits from steel, teflon and tiles

- cleaning equipment and ventilation ducts

- elimination of odors, germs and parasites

BOTTLING AND FILLING LINES

Since bottling and filling lines are the last steps in which the product can be microbiologically compromised, industrial dry vapor steam cleaners are an excellent tool to clean and sanitize the lines, without introducing any chemical or product that might affect and even contaminate flavors.

Dry steam can penetrate nooks and crannies and the fact that it also has a quite instant heat transfer, allows a quick, safe sanitation of all parts of the bottling line. Also, the volume of water used in steam cleaning of bottling and filling lines is a very limited if compared to the amount of water used with most conventional methods.

Areas of application: some examples which include:

- sanitizing and cleaning of bottling lines and nozzles

- removal of moulds and bacteria

- cleaning of conveyor belts, chains, belts, rollers and gaskets

- removal of deposits

- polishing of chrome-plate surfaces

- sanitizing of machinery and floors

BEVERAGE EQUIPMENT / WINERY AND BREWERY

The beverage industry, including wineries, breweries, soft drinks and other beverage manufacturers, use tanks, barrels, conditioning containers and automated bottling lines. Conveyors tend to collect dirt; storage tanks and vessels are subject to the build-up of deposits and crusts from the product processed in the plant.

Steam cleaners are the ideal, easiest tools to clean and sanitize the beverage areas and the different types of equipment (pipes, taps, nozzles, etc.), as well as all stainless steel surfaces. The inside of wine barrels is hard to reach and clean; yet, with the right steam jet system you will efficiently remove all kind chemical residues, bacteria and deposits.

Areas of application: some examples which include:

- cleaning & sanitizing of large stainless tanks, oak barrels

- cleaning & sanitizing bottling lines, piping systems and conveyor belts

- removal of deposits, mould and bacteria

- sanitizing of filters, glasses, sanitary fittings and floors

- cleaning of decanting piping and machines

HEALTHCARE

Dry steam is the successfully proven alternative to traditional hospital cleaning and provides a chemical-free solution able to kill germs, pathogens and harmful bacteria on contact in an environment where highly demanding procedures and protocols are required.

Quality dry steam cleaners are the ideal tools for hospitals, nursing homes, and assisted living facilities.

Whether you are cleaning and sanitizing waiting rooms, restrooms, patient rooms, operating rooms or durable medical equipment, dry steam cleaning technology help safeguard patients, staff and visitors against germs and harmful bacteria.

Areas of application: some examples which include:

- sanitizing of ambulatories, medical cabinets and operating rooms

- cleaning and sanitizing of medical equipment

- sanitizing of mattresses, pillows and beds

- deep cleaning of floors and waiting rooms

- cleaning and sanitizing of wheelchairs, stretchers and ambulances

HOSPITALITY

Steam cleaning is the ideal solution for hospitality cleaning where high standards of cleanliness and hygiene are paramount: quick, easy, cost effective, no need of chemicals. High temperature steam helps clean and sanitize a huge range of surfaces in your venue (floors, carpets, sinks, windows, bench tops, bathrooms, hoods, etc) ensuring your restaurant, café, bakery or fast food shop are hygienically clean.

Areas of application: some examples which include:

- sanitizing of tiles

- cleaning of parquet and wood strips

- removal of stains and odors from carpets, coverings and seats

- sanitizing of bathrooms

- cleaning of lifts, ventilation ducts, windows, mirrors

- cleaning and disinfecting of food processing areas

SPA & BEAUTY FARMS

Healthcare centres, beauty farms and spas are places with specific requirements in terms of sanitation and hygiene, in view of the daily flow of users they normally have. Further, moist environments and high temperatures are the right conditions that promote bacteria and moulds growth. The temperature our steam cleaners reach grants full sanitation and deep cleaning of the environment: using quality steam to sanitize also means savings in terms of time and money with an eco-friendly tool, with no need to add chemical agents and disinfectants.

Areas of application: some examples which include:

- removal of bacteria, mould and deposits

- sanitizing of contact surfaces

- cleaning of glass, mirrors and parquet

- sanitizing of saunas and steam baths, whirlpools, massage rooms

- sanitizing of poolside, showers and changing rooms

- removal of stains and odors from carpets, coverings and chairs

COMMUNITY

Professional dry vapor steam cleaners grant high standards of hygiene and cleaning of rooms and equipment in gathering places. Dry vapor steam cleaning is the actual cost-effective technology for places such as public buildings, community kitchens, schools sport centers, retirement communities, saunas and health spa resorts, etc. Most of the equipment used in there require specific, careful maintenance which cannot be granted by traditional cleaning systems.

Efficient, reliable and safe, our professional dry vapor steam cleaners meet the ever tighter quality standards on cleaning and hygiene in different sensitive areas.

Areas of application: some examples which include:

- sanitizing of plastic-chromed equipment

- sanitizing of filters and gratings

- sanitizing of bathrooms, showers and changing rooms

- sanitizing of dining halls

- removal of deposits, mould and bacteria

- sanitizing of poolside

INDUSTRY

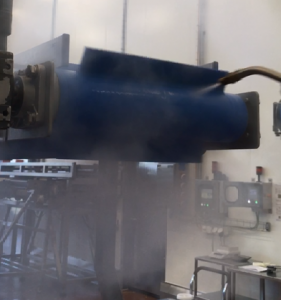

The dry vapor steam technology is the ideal tool when heavy duty cleaning and degreasing are required in manufacturing facilities and related equipment. The continuous steam system provides constant steam quality which can be adjusted by volume and dryness. Water flow and heating power can be controlled and adapted by an electronic control system. Industrial dry vapor steam cleaners exploit the cleaning and sanitation power of high temperature in cleaning food processing plants, industrial machinery, coils, conveyor belts, packaging machinery, process lines and a variety of other areas in manufacturing.

- hygiene and sanitation in industrial environments

- hygiene and sanitation in industrial environments

- hygiene and sanitation in industrial environments

- hygiene and sanitation in industrial environments

Areas of application: some examples which include:

- removal of greasy residues

- cleaning of mechanical parts

- cleaning of floors

- cleaning of motors and crankcases

- cleaning of transmission belts

- sanitizing of filters and gratings

- cleaning of switchboards

- sanitization of laboratories

- degreasing and polishing of shields

- removal of grease and scales from fixed structures, trackways and stairs

- cleaning of heat exchangers and air-conditioners

MEANS OF TRANSPORTATION

Steam is essential to clean, sanitize and remove all stains and odors from the interiors of vehicles, trains, aircrafts and ships. The temperature our steam cleaners reach grants full sanitation and deep cleaning of tissues; it’s the most effective tool to get rid of ticks, fleas or lice that can nest in the tissues.A full range of accessories are also provided for an easy, safe and quick cleaning under any circumstances, even in case of little room for movement.

Areas of application: some examples which include:

- removal of odors and traces from tissues, interiors of cars, trains, ships and aircrafts

- removal of deposits, mould and bacteria

- safe cleaning and sanitizing of upholstery

- cleaning and sanitizing of refrigerating rooms

- deep cleaning of armchairs, chairs, floors

- cleaning and sanitizing of toilet facilities

CAR WASH SERVICE

Using steam to professionally clean and detail cars has become more widely used by many auto detail shops and mobile detail businesses: it’s a faster way to clean – not only the car’s interiors but also the exteriors – more exhaustively than traditional methods do, with high-quality cleaning results.

When done correctly and by using the best steam car wash machine, the cleaning process is completely safe. The added advantage is that quality steam also has sanitizing features and can be defined an “eco-sound” tool: very little water is needed to wash a car, with no waste water run-off either. You can get amazing cleaning results without using any harsh chemicals or strong detergents that can potentially damage the paint or the finishing of your car. Car paint is highly weather resistant and can endure extreme cold and heat. Steam supplied from steam car wash machines has no impact on the paint of automobiles. Moreover, steam acts gently on the car surface and doesn’t cause scratches. In fact, scratches are normally caused by minute dirt and dust particles, which get rubbed against the surface when not removed before cleaning.